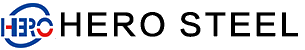

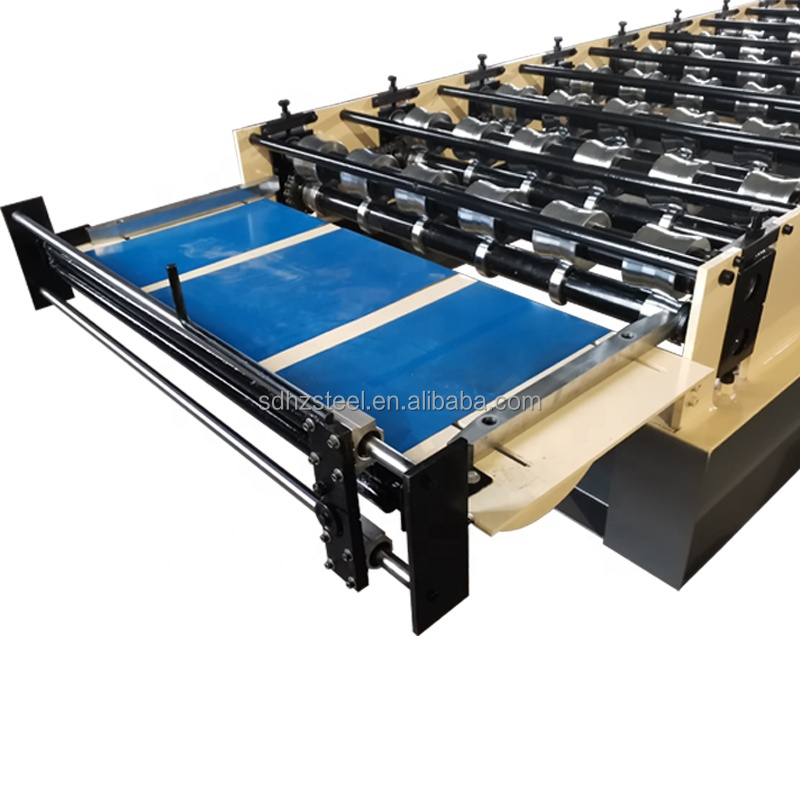

Main forming part

>Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and

coated with hard chrome

>Shaft: 70mm manufactured with 45# high grade steel by CNC machine tools

>Supporting frame: steel wallboard to guide the forming station bearing basement

>The finished products will change if using different material and thickness

>Driving of machine:by one inch chain

Description